GCM-Series

ROTO GRAVURE CYLINDER

De-Chrome Machine Auto/Manual

Description

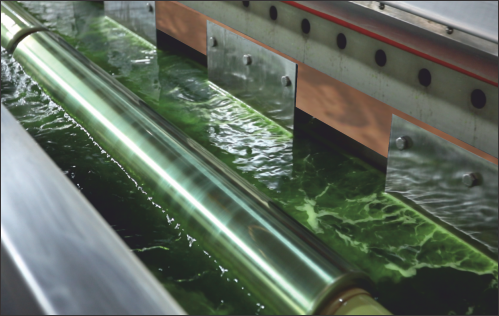

De-chroming is an electrochemical process is used to remove the chrome layer from workpieces without damaging material. It is a gentle process that allows for the reuse of components with a chrome coating.

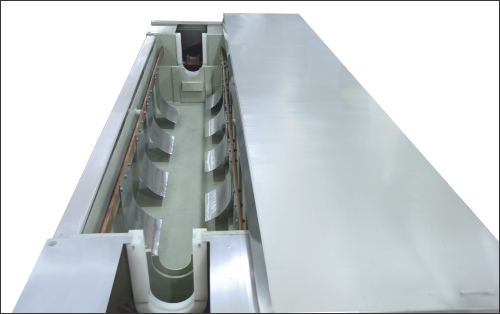

Process During the de-chroming process, an electrolytic solution is used an ambient temperature, with the current direction opposite to that used during chrome plating. Components with a coating can be easily disassembled, de-chromed, and re- coated without the need to replace specific parts entirely. By reusing components, waste is reduced and the environment is protected. Whole machine body is made up of by SS sheet (SS-316 grade)

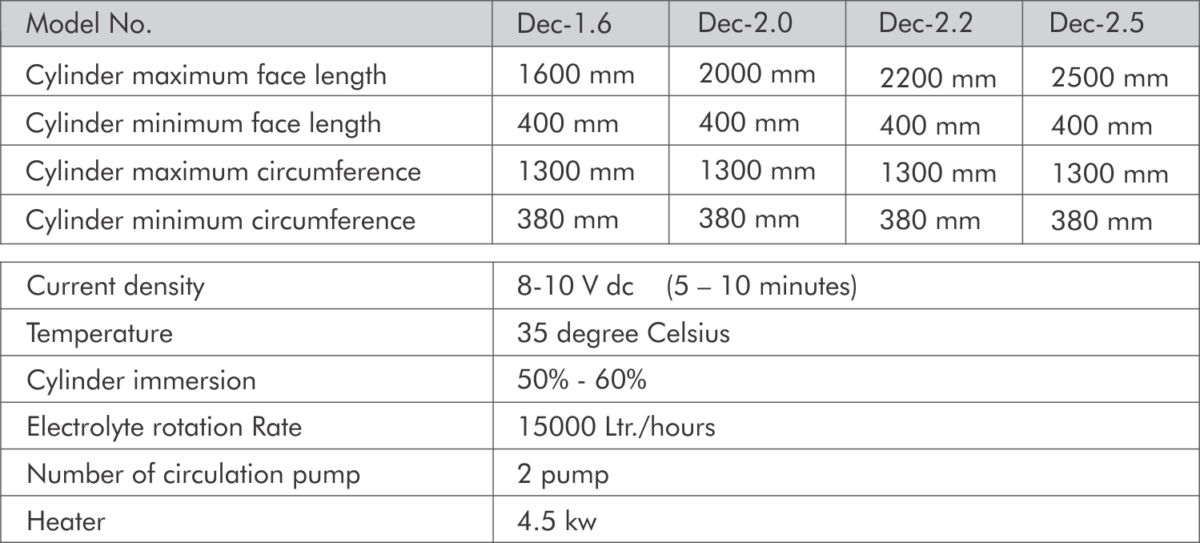

Technical Specification